MIL-DTL-18375H

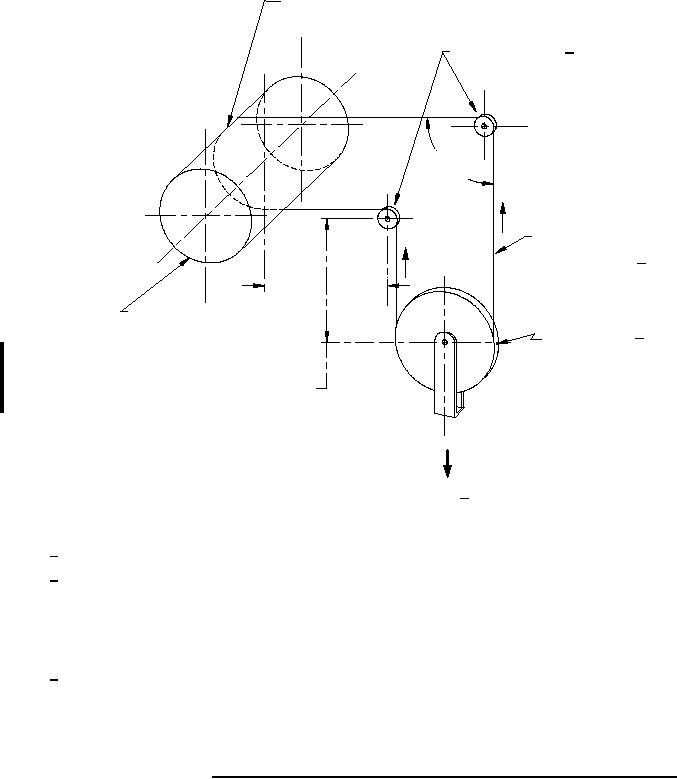

Clamp wire rope

to the drum

Test sheaves 3/3/ (see figure 2)

Test sheaves (see fig. 2)

90°

T2

Wire rope speciman

T1

under tension 1/

13.5 in. min.

Drum 16 in. dia. oscillating

rate 120 reversals per

Idler Sleeve 3/

min. and equipped

11.5 in. dia. min.

with a counter

13.5 in. min.

Force 2/

NOTES:

1/ Tension load per table II T1 = T2 = w/2

2/ Force necessary to develop the applicable tension load = w = w1 + w2 + w3, where

w1 = weight of idler sheaves

w2 = weight of hanger

w3 = weight added to hanger to make the total weight "w" equal to twice the applicable tension load

3/ All sheaves shall be supported on suitable ball or roller bearing, or on shaft extensions supported on suitable

ball or roller bearings.

4/ The dimensions of the test sheaves are test parameters only and are by no means intended as design criteria.

FIGURE 1. Diagram of endurance testing machine and conditions of the test.

14

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business