MIL-DTL-18375H

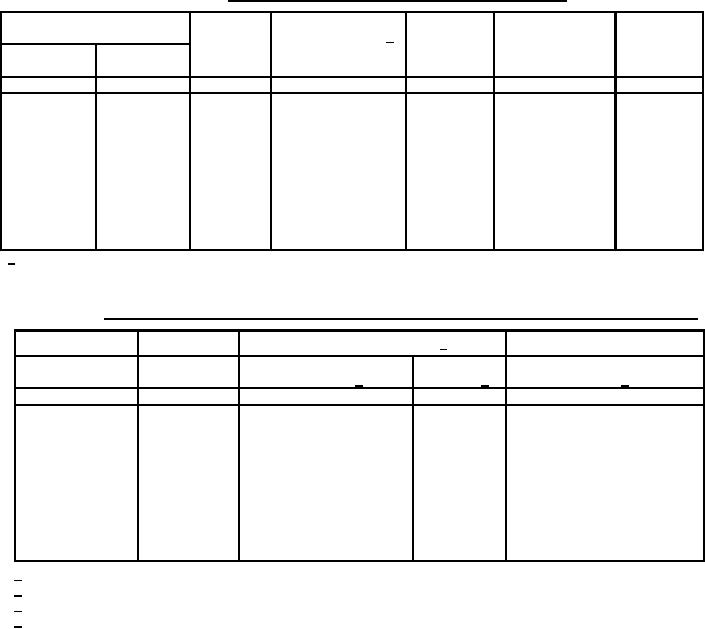

TABLE I. Wire rope construction and physical properties.

Construction

MBS before

Approximate

Diameter of wire rope

Tolerance

Allowable increase of

endurance testing

weight per

on diameter

diameter at cut end 1/

100 ft.

(plus only)

Nominal

Minimum

(reference)

in.

in.

in.

in.

lbs.

lbs.

1/16

0.062

0.010

0.009

7x7

360

0.75

3/32

0.093

0.012

0.010

7x7

700

1.60

1/8

0.125

0.014

0.011

7 x 19

1,300

2.90

5/32

0.156

0.016

0.017

7 x 19

2,000

4.50

3/16

0.187

0.018

0.019

7 x 19

2,900

6.50

7/32

0.218

0.018

0.020

7 x 19

3,800

8.60

1/4

0.250

0.018

0.021

7 x 19

4,900

11.00

9/32

0.281

0.020

0.023

7 x 19

6,100

13.90

5/16

0.312

0.022

0.024

7 x 19

7,600

17.30

3/8

0.375

0.026

0.027

7 x 19

11,000

24.30

1/ The allowable increase in diameter shall be applied to the actual diameter of the wire rope being tested.

TABLE II. Wire rope endurance test parameters and breaking strength after endurance testing.

Endurance test parameters 1/

Number of

MBS after endurance

Nominal diameter

Construction

Minimum tension load

reversals 3/

testing 4/

of wire rope

(-0, + 10%) 2/

in.

lbs.

lbs.

1/16

7x7

5.0

70,000

216

3/32

7x7

9.0

70,000

420

1/8

7 x 19

18.0

70,000

780

5/32

7 x 19

24.0

130,000

1,200

3/16

7 x 19

37.0

130,000

1,740

7/32

7 x 19

50.0

130,000

2,280

1/4

7 x 19

64.0

130,000

2,940

9/32

7 x 19

78.0

130,000

3,660

5/16

7 x 19

90.0

130,000

4,560

3/8

7 x 19

120.0

130,000

6,600

1/

The tension loads and number of reversals are test parameters only and are by no means intended as design criteria.

Tension load is equal to one-half the weight (w) as shown in figure 1.

2/

3/

2 reversals = 1 cycle. 13 1/2 inches of travel in one direction and return.

Each value is equal to 60 percent of the original MBS of the wire rope as shown in table I.

4/

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business