MIL-DTL-87161F

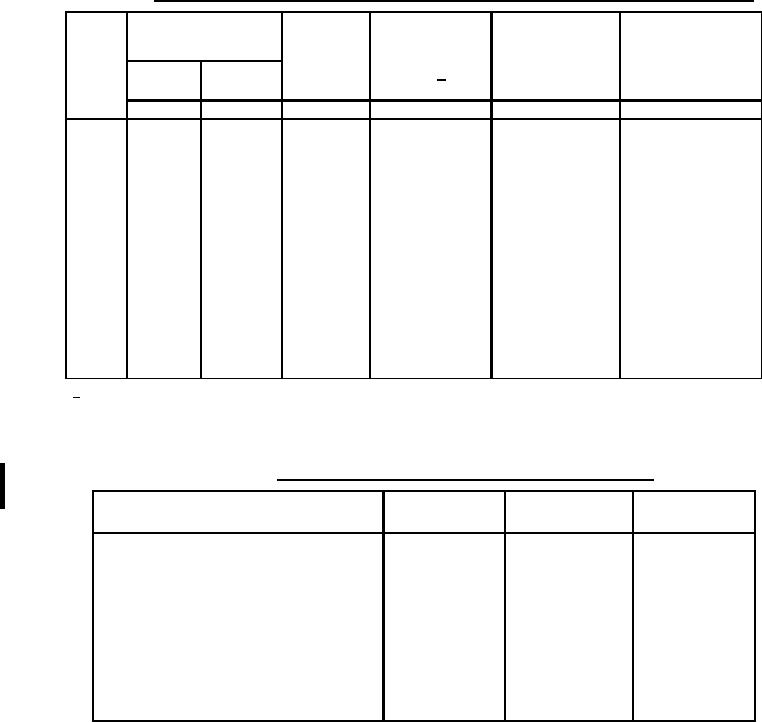

TABLE I. Construction, physical properties of type I and II, composition A and B wire strand.

MBS

Approximate

Tolerance

Allowable

Diameter of

composition

weight

on diameter

increase in

wire strand

(plus only)

diameter at the

A&B

per

Nominal

Minimum

100 ft. (30.5 m)

end 1/

Strand

reference

type

in.

in.

in.

in.

lbs.

lbs.

0.25

185

0.006

0.003

0.031

1/32

I

0.55

375

0.008

0.005

0.046

3/64

I

0.55

375

0.008

0.005

0.046

3/64

II

0.85

500

0.009

0.006

0.062

1/16

I

0.85

500

0.009

0.006

0.062

1/16

II

1.40

800

0.009

0.008

0.078

5/64

II

2.00

1,200

0.010

0.009

0.093

3/32

II

2.70

1,600

0.010

0.009

0.109

7/64

II

3.50

2,100

0.011

0.013

0.125

1/8

II

5.50

3,300

0.016

0.013

0.156

5/32

II

7.70

4,700

0.019

0.013

0.187

3/16

II

10.20

6,300

0.020

0.015

0.218

7/32

II

13.50

8,200

0.021

0.018

0.250

1/4

II

21.00

12,500

0.024

0.022

0.312

5/16

II

30.00

17,500

0.027

0.026

0.375

3/8

II

1/ The allowable increase in diameter shall be applied to the actual diameter of the wire strand being tested.

TABLE II. Qualification and conformance tests and inspections.

Tests

Requirement

Qualification

Conformance

paragraph

paragraph

paragraph

Examination of product

Weight of zinc coating test, comp. A

Preforming check

Breaking strength

Stretch test

Adherence of coating

Ductility of steel

4.4.4 - 4.4.4.1

4.4.4 - 4.4.4.1

Test loading

3.5 - 3.5.3

Identification of product

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business