MIL-DTL-87218E

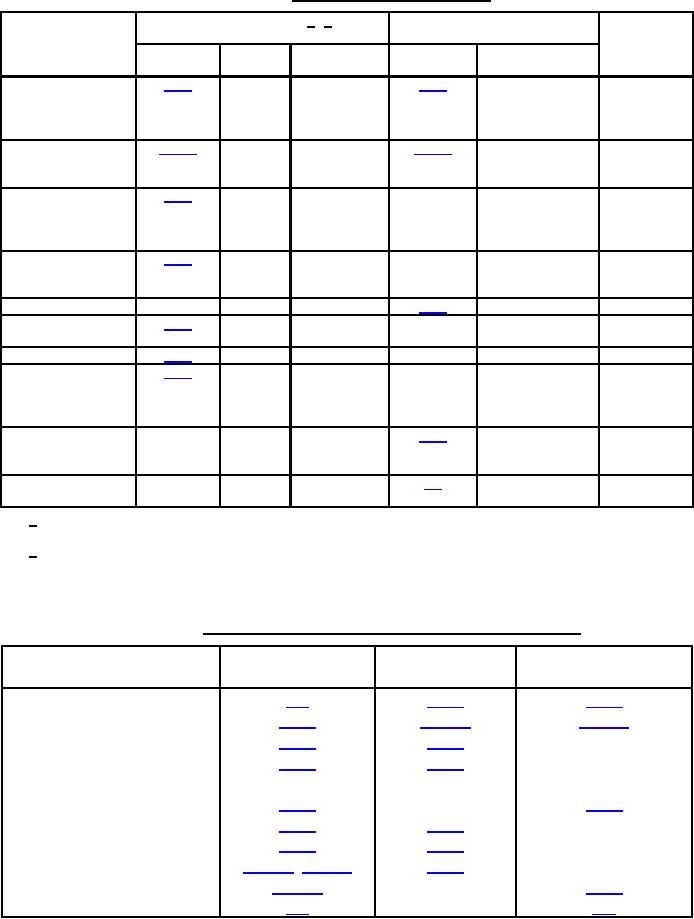

TABLE III. Summary of test specimens.

Qualification testing 1/ 2/

Conformance testing

(each type and class)

Comments

Test

Paragraph

No. of

Comments

Paragraph

No. of

specimens

specimens

Examination of

-

-

100% of all lots

Retention test

product

every 5 years

or on process

change

Breaking strength

3

5 to 12 foot

2 of each lot of 40

Test only on

length

or less: 3 of each

lockclad

lot of 41 - 110

assemblies

Elongation

3

5 to 12 foot

-

-

Retention test

length

every 5 years

or on process

change

Coefficient of thermal

3

2 to 4 foot

-

-

Retention test

expansion

length

on process

change

Proof loading

-

-

-

100% of all lots

-

Temperature limits

3

5 to 12 foot

-

-

-

length

Weight

3

2 foot length

-

-

-

Concentricity

3

3 Sectioned

-

-

Retention test

pieces

every 5 years

or on process

change

Straightness

-

-

-

Visual inspect

-

100%. Sample

measure all lots

Identification of

-

-

-

100% of all lots

-

product

1/ When qualification testing has been successfully accomplished on one type and class of cable, only sampling

qualification testing is required on the type and class not previously tested.

2/ Qualification test data for two different size cables shall be submitted, for consideration, to the Government agency

responsible for qualification approval.

TABLE IV. Qualification and conformance tests and inspections.

Tests

Requirements

Qualification

Conformance

paragraph

paragraph

paragraph

Examination of product

Breaking strength

Elongation

-----

Coefficient of thermal

-----

expansion

Proof loading

-----

Temperature limits

-----

Weight

-----

Diameter and concentricity

-----

Straightness

-----

Identification

-----

14

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business