MIL-DTL-83420M

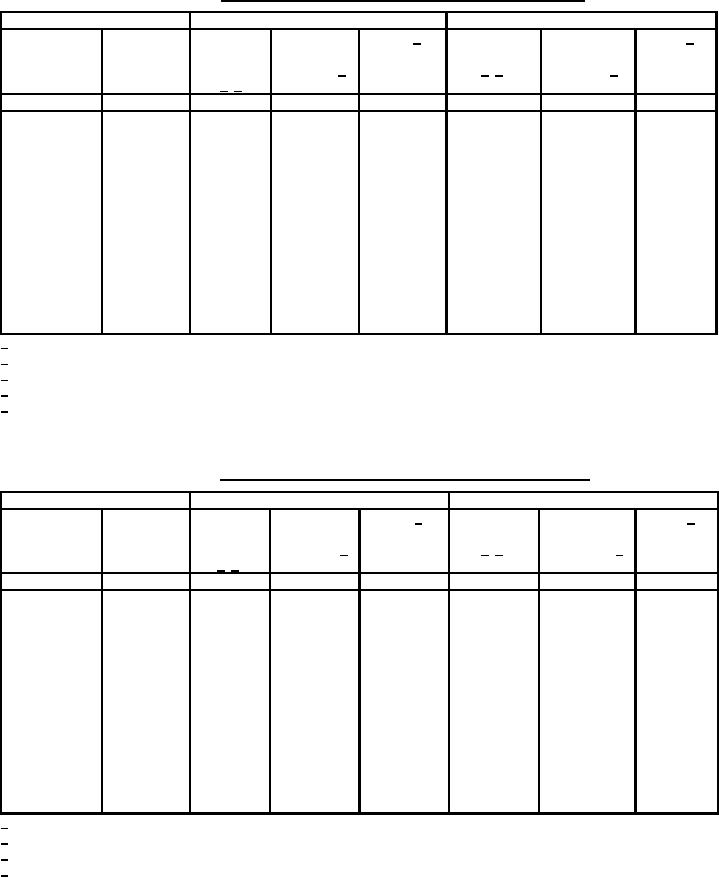

TABLE III. Breaking strength of type I after endurance testing.

COMPOSITION

A

B

Construction

Tension

MBS 4/

Number

MBS 5/

Number

Nominal

Tension load

load

of

of

diameter of

(-0%,+10%)

(-0,+10%)

reversals 3/

reversals 3/

bare wire rope

1/ 2/

1/ 2/

in.

lbs.

lbs.

lbs.

lbs.

66

70,000

1.0

55

70,000

1.0

3x7

1/32

162

70,000

3.0

135

70,000

3.0

7x7

3/64

288

70,000

5.0

240

70,000

5.0

7x7

1/16

288

70,000

5.0

240

70,000

5.0

7 x 19

1/16

552

70,000

9.0

460

70,000

9.0

7x7

3/32

552

70,000

9.0

500

70,000

9.0

7 x 19

3/32

1,056

70,000

18.0

1,000

70,000

18.0

7 x 19

1/8

1,440

130,000

24.0

1,400

130,000

24.0

7 x 19

5/32

2,220

130,000

37.0

2,100

130,000

37.0

7 x 19

3/16

3,000

130,000

50.0

2,800

130,000

50.0

7 x 19

7/32

3,840

130,000

64.0

3,500

130,000

64.0

7 x 19

1/4

4,680

130,000

78.0

4,000

130,000

78.0

7 x 19

9/32

5,400

130,000

90.0

4,900

130,000

90.0

7 x 19

5/16

7,200

130,000

120.0

7,200

130,000

120.0

7 x 19

3/8

1/

Tension is equal to one half the weight (w) which includes idler sheave and hanger.

2/

The magnitude of the tension loads are test parameters only and are by no means intended as design criteria.

3/

1 cycle = 2 reversals

4/

Equal to 50 percent of the original MBS.

5/

Equal to 60 percent of the original MBS.

TABLE IV. Breaking strength of type II after endurance testing.

COMPOSITION

A

B

Construction

Tension

MBS 4/

Number

MBS 4/

Number

Nominal

Tension load

load

of

of

diameter of

(-0%,+10%))

(-0,+10%)

reversals 3/

reversals 3/

bare wire rope

1/ 2/

1/ 2/

in.

lbs.

lbs.

lbs.

lbs.

66

200,000

1.0

66

200,000

1.0

3x7

1/32

162

200,000

3.0

162

200,000

3.0

7x7

3/64

288

200,000

5.0

288

200,000

5.0

7x7

1/16

288

200,000

5.0

288

200,000

5.0

7 x 19

1/16

552

200,000

9.0

552

200,000

9.0

7x7

3/32

552

200,000

9.0

600

200,000

9.0

7 x 19

3/32

1,056

200,000

18.0

1,200

200,000

18.0

7 x 19

1/8

1,440

500,000

24.0

1,680

500,000

24.0

7 x 19

5/32

2,220

500,000

37.0

2,520

500,000

37.0

7 x 19

3/16

3,000

500,000

50.0

3,360

500,000

50.0

7 x 19

7/32

3,840

500,000

64.0

4,200

500,000

64.0

7 x 19

1/4

4,680

500,000

78.0

4,800

500,000

78.0

7 x 19

9/32

5,400

500,000

90.0

5,880

500,000

90.0

7 x 19

5/16

7,200

500,000

120.0

8,640

500,000

120.0

7 x 19

3/8

1/

Tension is equal to one half the weight (w) which includes idler sheave and hanger.

2/

The magnitude of the tension loads are test parameters only and are by no means intended as design criteria.

3/

1 cycle = 2 reversals

4/

Equal to 60 percent of the original MBS.

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business