MIL-DTL-83420M

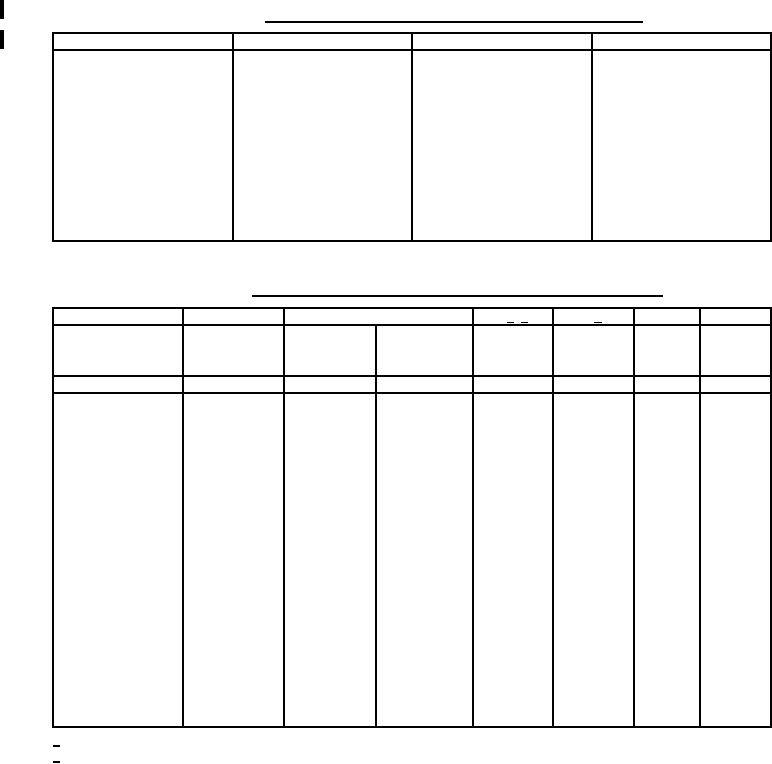

TABLE V. Qualification and conformance tests and inspections.

Tests

Requirement paragraph

Qualification paragraph

Conformance paragraph

Ductility of steel

Adherence of coating

Identification of product

4.4.2 - 4.4.2.2

4.4.2 - 4.4.2.2

3.7 - 3.7.1.1

Examination of product

Breaking strength

4.4.4 - 4.4.4.2

Endurance for type I

4.4.5 - 4.4.5.2

Endurance for type II

Stretch limits

4.4.7 - 4.4.7.1

Test load

-

4.4.8.1 - 4.4.8.1.3

3.3.3.1 - 3.3.3.2

Tin and zinc coating

-

Low temperature flexibility

-

Resistance to fluids

TABLE VI. Dimension of test sheave** used in type I endurance test.

C 1/ 2/

G 1/

D

Er

Sheave

Ratio to 1

Composition A

Nominal diameter

Construction

Composition

+1/64

+1/64

+.005

+.002

-65 °F

of wire rope (d)

A&B

-1/64

-1/64

-.000

-.000

(-54 °C) test

rm temp test

in.

in.

in.

in.

in.

0.025

0.562

3/8

0.703

-

18.0

3x7

1/32

0.025

0.750

3/8

0.814

23.0

-

3x7

1/32

0.025

0.562

3/8

0.703

-

12.0

7x7

3/64

0.025

0.750

3/8

0.891

16.0

-

7x7

3/64

0.036

0.750

3/8

0.938

-

12.0

7x7

1/16

0.036

1.000

3/8

1.188

16.0

-

7x7

1/16

0.036

0.438

3/8

0.625

-

7.0

7 x 19

1/16

0.036

0.594

3/8

0.782

9.5

-

7 x 19

1/16

0.052

1.220

3/8

1.406

-

13.0

7x7

3/32

0.052

1.313

3/8

1.594

14.0

-

7x7

3/32

0.052

0.656

3/8

0.938

-

7.0

7 x 19

3/32

0.052

0.891

3/8

1.172

9.5

-

7 x 19

3/32

0.069

0.875

3/8

1.250

-

7.0

7 x 19

1/8

0.069

1.188

3/8

1.562

9.5

-

7 x 19

1/8

0.086

1.484

3/8

1.953

9.5

9.5

7 x 19

5/32

0.102

1.781

1/2

2.343

9.5

9.5

7 x 19

3/16

0.118

2.078

1/2

2.734

9.5

9.5

7 x 19

7/32

0.134

2.375

1/2

3.125

9.5

9.5

7 x 19

1/4

0.150

2.671

1/2

3.515

9.5

9.5

7 x 19

9/32

0.167

2.969

9/16

3.907

9.5

9.5

7 x 19

5/16

0.200

3.562

9/16

4.687

9.5

9.5

7 x 19

3/8

1/ Reference numbers, not a mandatory dimension. Left to manufacturer's discretion.

2/ C=D+3d

** The dimensions of the test sheaves are test parameters only and are by no means intended as design criteria.

21

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business