MIL-DTL-8878L

3.5.2 Aluminum parts. Aluminum alloy shall be anodized per MIL-A-8625, type II,

class 1.

3.6 Dimensions. The dimensions of turnbuckle bodies, turnbuckle ends, and the locking

clip shall conform to those specified on the applicable MS sheet.

3.6.1 Threads. The internal threads in the turnbuckle bodies shall conform to

ASME B1.1 UNF-3B. Concentricity between tap hole and threads shall be such that the locking

clips can be installed with the terminals engaged to the cross hole for all locking slots (see 4.6.5.1).

3.7 Physical properties.

3.7.1 Rotational movement. The total angular clockwise and counterclockwise rotational

movement between turnbuckle body and turnbuckle end with locking clip installed shall not

exceed that specified in table I when subjected to 10 percent of the specified torsion load (see

4.6.1).

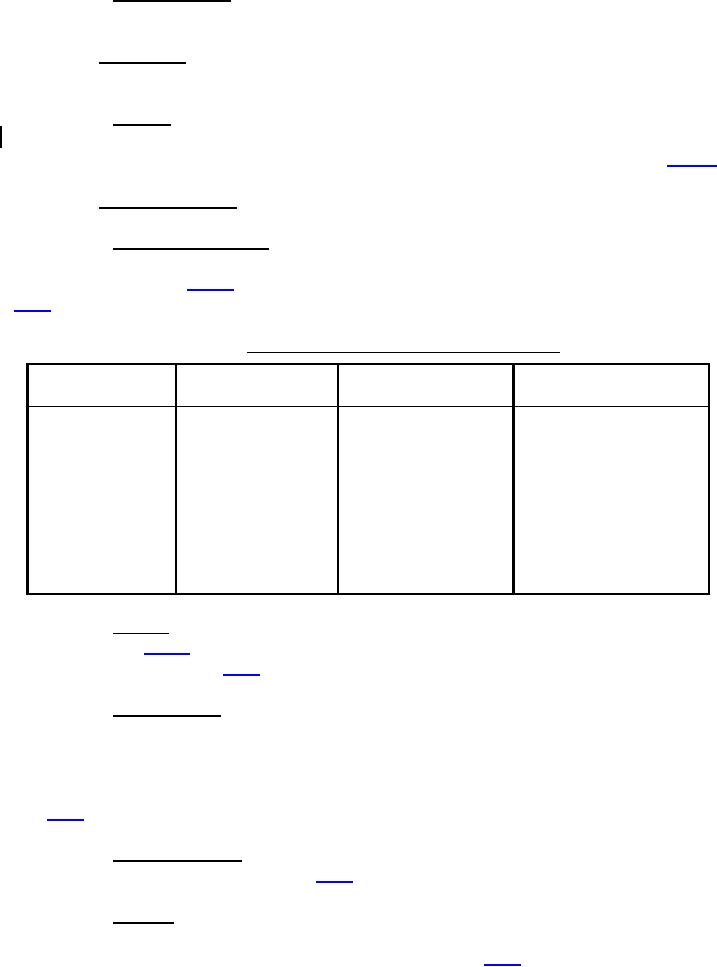

TABLE I. Torsion test loads and rotational movement.

MS sheet

Minimum torque

10% of torsion load

Rotation movement

dash number

(in-lbs)

(in-lbs)

(maximum degrees)

2

8

0.8

15

3

26

2.6

11

4

82

8.2

8

5

82

8.2

8

6

163

16.3

7

7

318

31.8

6

8

318

31.8

6

9

523

52.3

5

10

750

75.0

4

3.7.2 Torsion. Turnbuckle bodies and ends shall be capable of withstanding the torsional

loads specified in table I, applied clockwise and counterclockwise direction without permanent

deformation when tested per 4.6.2.

3.7.3 Tensile fatigue. Turnbuckle bodies and ends shall be capable of withstanding a

load equal to 60 percent of the minimum breaking strength (MBS) specified on the applicable

MS sheet, applied repeatedly in tension at a rate of approximately one cycle per second for 300

applications without failure, deformation, or permanent increase in overall length of any

component part in excess of 0.001 inch per inch in the direction of the application of load

(see 4.6.3).

3.7.4 Breaking strength. The MBS of turnbuckle parts shall not be less than the values

specified on the applicable MS sheet (see 4.6.4).

3.7.5 Bending. Turnbuckle ends shall withstand bending through an angle of 90 degrees

without cracking or fracture. Locking clip formed radii shall withstand straightening so that the

test sample becomes approximately a straight length of wire (see 4.6.6).

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business