MIL-DTL-8878L

4.6.2 Torsion. A turnbuckle assembly containing the sample component part with a

locking clip installed shall be subjected to the applicable torque load specified in table I, applied

in a clockwise and counterclockwise direction for five complete cycles. The turnbuckle shall

then be disassembled and the sample shall be inspected for evidence of failure per 3.7.2. There

shall be no evidence of cracks in the sample turnbuckle part of locking clip. Deformation of the

turnbuckle or locking clip is acceptable if parts can be disassembled by hand.

4.6.3 Tensile fatigue. A turnbuckle assembly containing the sample component part

shall be subjected to a tension load equal to 60 percent of the MBS specified on the applicable

MS sheet for the sample, applied repeatedly in tension at a rate of approximately one cycle per

second for 300 applications. The turnbuckle assembly shall be disassembled and the sample

parts shall be inspected for conformance to 3.7.3. Elongation of the sample turnbuckle part(s)

shall be determined per ASTM E8/E8M.

4.6.4 Breaking strength. A turnbuckle assembly containing the sample component part

shall be tested for MBS by an appropriate means per ASTM E8/E8M. The MBS value is that

specified on the applicable MS sheet. There shall be no evidence of failure in the sample part. It

may be necessary to fabricate special high strength fixtures for attaching to the parts to be tested

in order to develop the required loads.

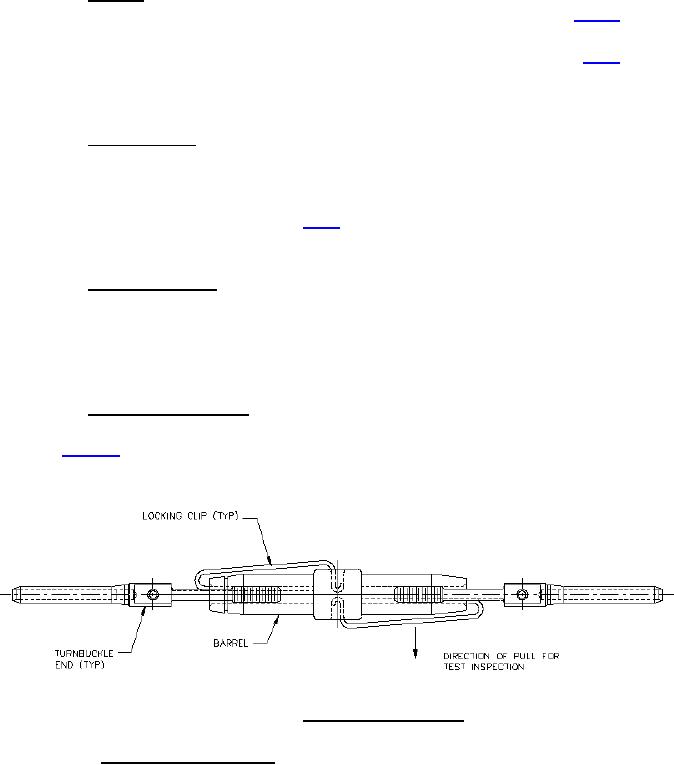

4.6.5 Locking clip retention. A locking clip shall be installed in a turnbuckle per the

instructions specified on MS33736. A direct pull of 15 lbs. shall be applied to the locking clip as

shown on figure 1. The locking clip shall not break nor shall the retention feature become

disengaged.

FIGURE 1. Locking clip retention.

4.6.5.1 Functional acceptability. The turnbuckle body and mating terminals must be

assembled and the locking clip inserted in each end of the turnbuckle body. After removing

clips, except for -2, the terminals are rotated one half turn and the locking clip inserted once

again. This functional assembly requirement tests every combination of the locking capability of

the assembly.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business