MIL-DTL-8878L

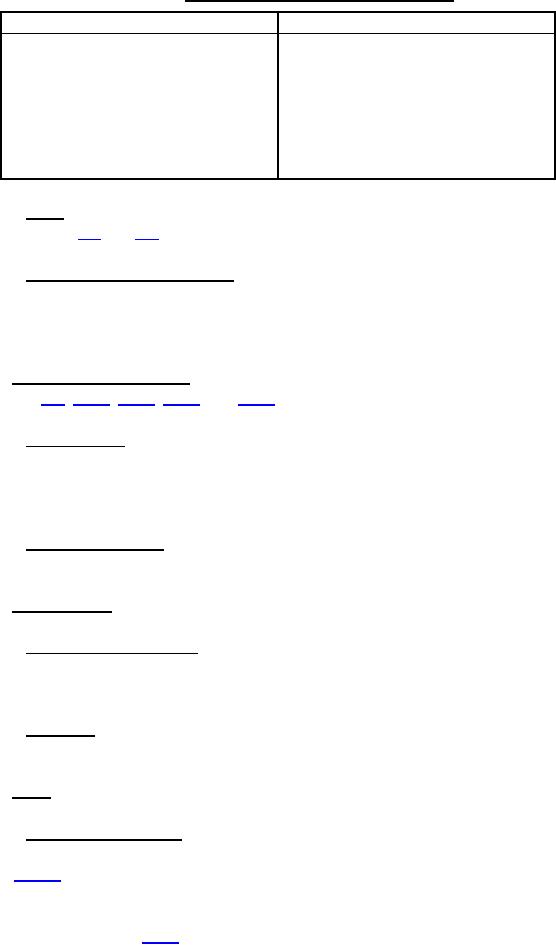

TABLE II. Qualification test sample distribution.

Test

Quantity

Rotational movement

1

Torsion

Use rotational movement sample

Hardness

Use rotational movement sample

Tensile fatigue

1

Breaking strength

1

Locking clip retention

1

Bending

Use breaking strength sample

4.3.2 Tests. The qualification tests of turnbuckle component parts shall consist of all the

4.3.3 Maintenance of qualification. At specified intervals determined by the qualifying

activity, the manufacturer must be able to demonstrate that the company still has the capabilities

and facilities necessary to produce the QPL items in accordance with this specification and in

accordance with the provisions governing qualification specified in SD-6.

4.4 Conformance inspection. Conformance tests shall consist of examinations and tests

4.4.1 Inspection lot. An inspection lot shall consist of turnbuckle component parts of the

same type, size, and material produced under the same manufacturing conditions. The unit of

inspection shall be one turnbuckle component part except for hardness and examination of

product.

4.4.2 Hardness sampling. The unit of inspection shall be one brass turnbuckle body per

stress relief batch.

4.5 Examinations.

4.5.1 Examination of product. Each sample part shall be examined for conformance to

the material, design, dimensional, protective treatment, marking, workmanship, and penetrant

inspection requirements of this specification and the applicable MS sheet.

4.5.2 Sampling. ASQ Z1.4 shall be used as a guide in the development of contractor's

statistical techniques to assure the components meet all requirements specified herein.

4.6 Tests.

4.6.1 Rotational movement. A turnbuckle assembly containing the sample component

part with a locking clip installed, shall be subjected to 10 percent of the applicable torque load

specified in table I, applied in a clockwise and counterclockwise direction. The total relative

angular rotation between the turnbuckle end and turnbuckle body (less the free play) from the

extreme of one direction (clockwise) to the extreme of the other (counterclockwise) shall be

measured for conformance to 3.7.1.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business